Observation of the current study states that the top effect group challenges such as the security of data and reliability of technologies can be mitigated by enabling blockchain technologies.

With the implementation of IIoT technologies, the manufacturing processes become conciliatory, effective and traceable in real time. Further, the authors tried to mitigate observed challenges with the help of blockchain technology.

#LEARNING FACTORY ROOM 122 TRIAL#

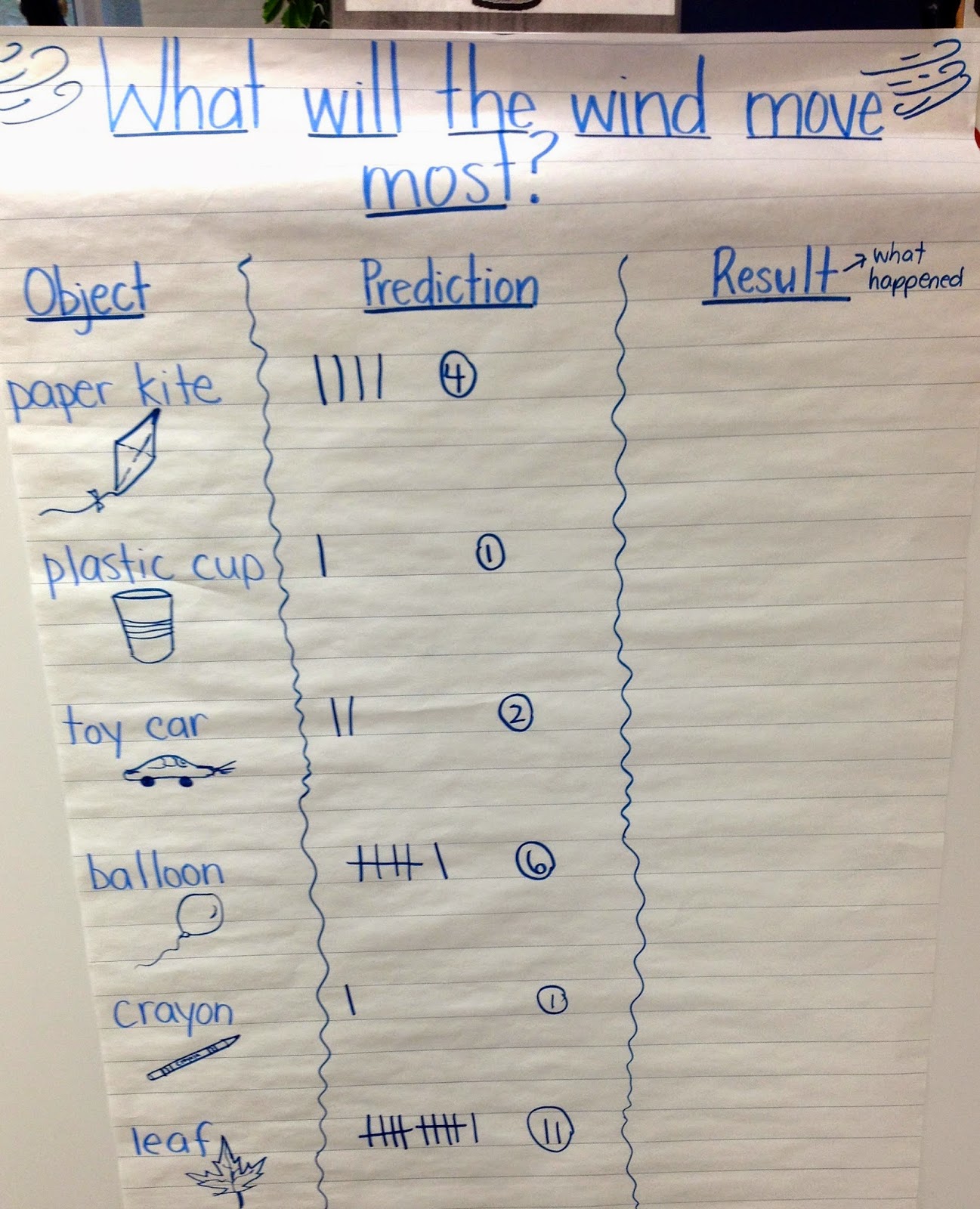

On the fundament of responses received from industrial experts, the Decision-Making Trial and Evaluation Laboratory (DEMATEL) technique has been used for categorizing these challenges into cause and effect groups. To collect information from Indian manufacturing SMEs, a survey tool was formed in the form of a questionnaire. There were ten challenges of IIoT implementation identified from the literature review and experts’ opinions. This research paper aims to recognize and analyze the challenges faced while implementing IIoT technologies in manufacturing SMEs and tries to find the possibility of mitigating challenges by blockchain technology. This digitalization can help in achieving new design changes, efficient production scheduling, smart manufacturing and unrestricted on-time delivery of quality products. Modern digitalization includes a mix of technologies such as the industrial internet of things (IIoT), the internet of things, cyber-physical system and big data analytics. In the new normal, the digitalization of manufacturing SMEs can be the path breaker. The modern scenario of customization, personalization and multi-restrictive working because of pandemics has affected the operations of manufacturing small and medium enterprises (SMEs). The purpose of this methodology is to categorise the challenges into cause and effect group. Finally, the important role of FPGAs to implement ML solutions is discussed. After that, we talk about how ML helps us achieve automation in decision making. In this chapter, we try to cover challenges faced in IIoT then present recently developed ML-based solutions.

Thus, integrating AI-enabled approaches into the fog and edge computing is a critical approach to overcome the obstacles and achieve intelligent IIoT. As AI-enabled frameworks normally need secure and private cloud services to process data accumulated in the industry, it causes some difficulties like latency, energy consumption, reliability, etc. Leading Data scientists to face the dilemma of choosing machine learning approaches that suit their needs and expectations. The industries whether limited to small businesses or large, are in need of machine learning approaches to overcome difficulties created by the data accumulated through web applications, management systems, sensors, and actuators. The Industrial Internet of Things (IIoT) is a model transformation, in the domain of the manufacturing industry. The revolution in industrial operations and productions triggered by IoT is like a newborn child that has a lot to be taken care of till reaching its maturity and being able to act independently. IIoT, altering the way industrial enterprises function daily to improve efficiency and performance levels. Therefore, the industry is being revolutionised by IIoT can monitor the transport, supply of the goods,Ĭonsult details on things in warehouses, and check the conditions related to product storage and delivery andĪllow all dispersed and outsourced operations to be monitored. The field of manufacturing are identified and discussed. Finally, twenty-nine significant applications of IIoT in

Smart Transformations made into the manufacturingįield through IIoT Culture are discussed diagrammatically.

The primary benefitsĪnd features of IIoT in manufacturing are discussed in detail. This paper provides an overview of the IIoT and the technologies that underpin it. IIoT is fundamental to transforming cyber-physical systems and production processes through big data and analytics. To provide remote access, effective monitoring, better data collecting, analysis, & exchange etc. IIoT refers to linked devices, sensors, and other equipment that may be networked in the industrial environment Of as a powerful connected industrial system with materials, parts, equipment, tools, inventory, and logistics thatĬan transmit data and communicate with one another in the age of the Industrial Internet of Things (IIoT). Now a day's manufacturing has become more intelligent and data-driven.

0 kommentar(er)

0 kommentar(er)